Technology

Technology

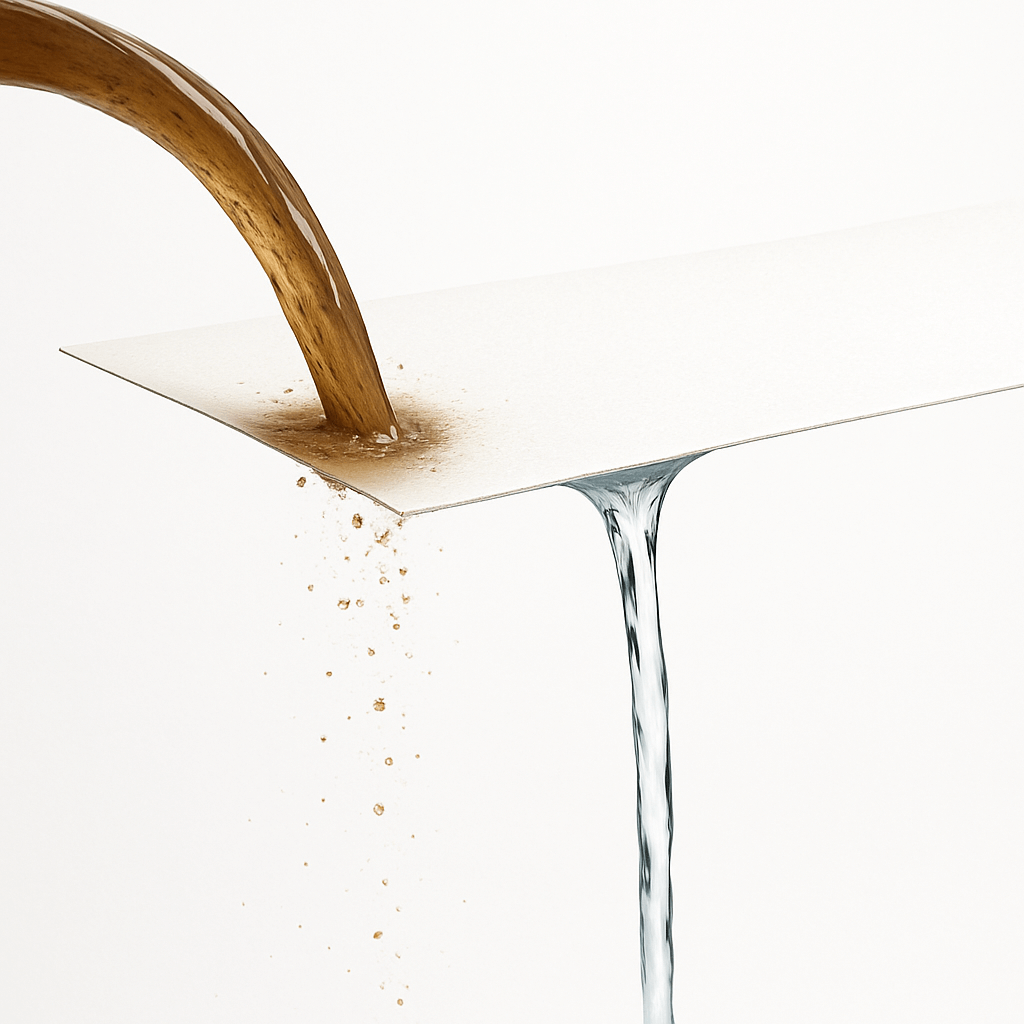

At the heart of every Pacific membrane lies a story told in

nanometres—a journey through polymeric layers, selective

permeation, and molecular rejection.

Our membranes are engineered using thin-film composite (TFC) technology, built on a base of cross-linked polysulfone substrates and ultra-selective polyamide layers. This layered approach allows us to tailor membranes for precise rejection rates, optimal flow, and extended life under diverse operating conditions.

Reverse Osmosis

Reverse Osmosis (RO) is one of the most effective methods for purifying water. In this process, water is passed through a semipermeable membrane that allows only water molecules to pass. RO membranes have extremely small pores, typically less than 1 nanometer (0.001 µm). The MWCO is around 100 Daltons or lower, allowing RO to reject nearly all dissolved solutes, including monovalent ions (e.g., sodium, chloride), divalent ions, organic molecules, and even small contaminants like bacteria and viruses. It produces nearly pure water, with only trace amounts of small molecules or ions passing through. This technology is widely used in drinking water purification, seawater desalination, and industrial water treatment.

Key Benefits:

- Health protection: Reduces exposure to harmful substances like heavy metals and chemical pollutants.

- Ultrapure Water: Produces high-purity water for laboratories, pharmaceuticals, and electronics manufacturing.

- Versatile: Suitable for residential, commercial, and industrial water treatment needs.

- High contaminant rejection: Removes a wide range of contaminants, including salts, heavy metals, and microorganisms.

- Non-chemical operation: Ideal for both residential systems and large-scale industrial water treatment.

Applications:

- Drinking Water Production: Removes contaminants like heavy metals, nitrates, fluoride, and organic pollutants from municipal or well water.

- Desalination: Converts seawater or brackish water into potable water by removing salts (e.g., in coastal regions or arid areas).

- Boiler Feedwater Treatment: Removes minerals to prevent scaling in power plants and industrial boilers.

- Food and Beverage Industry: Concentrates juices, dairy products, or sugars, and purifies process water.

- Pharmaceuticals: Produces water meeting stringent purity standards for drug manufacturing.

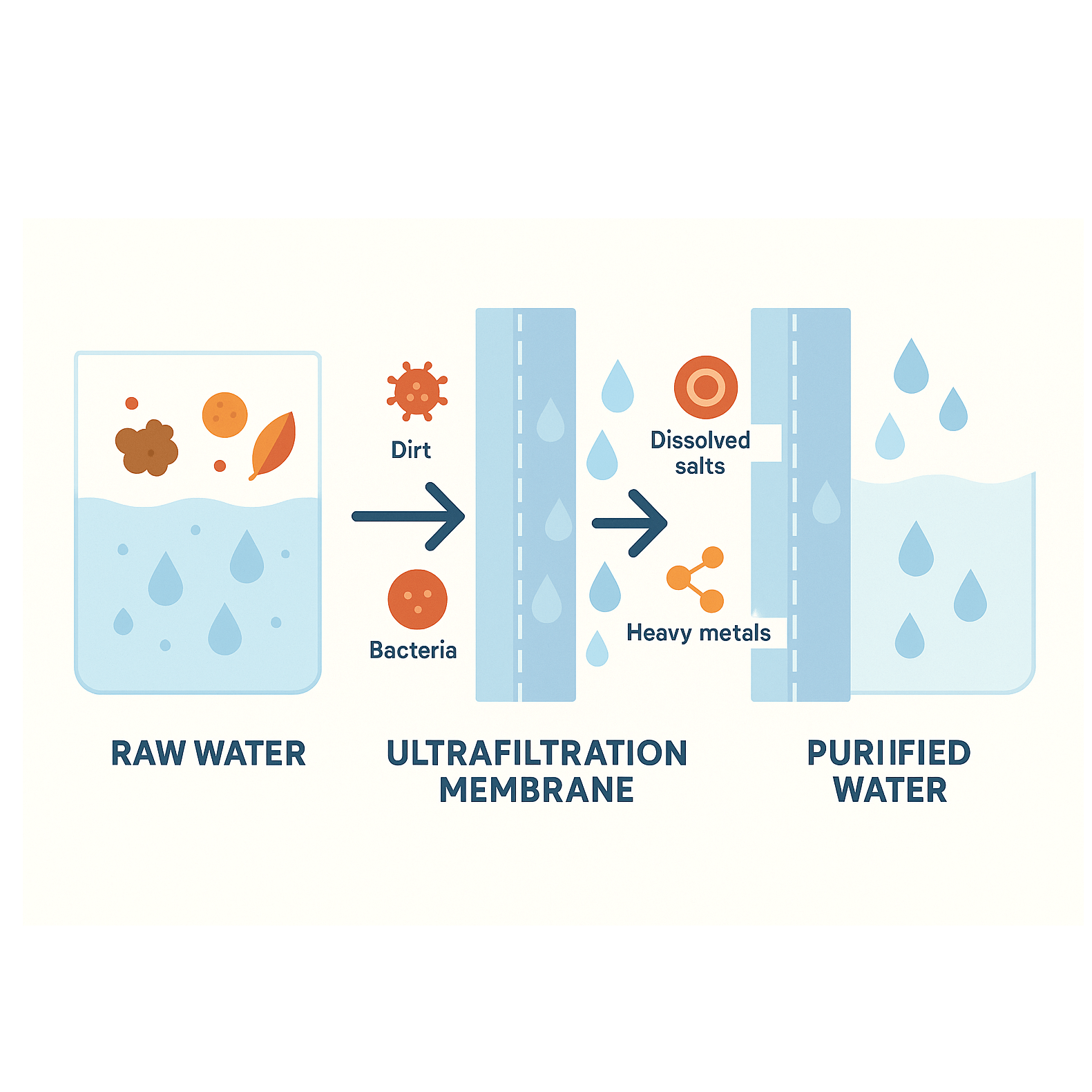

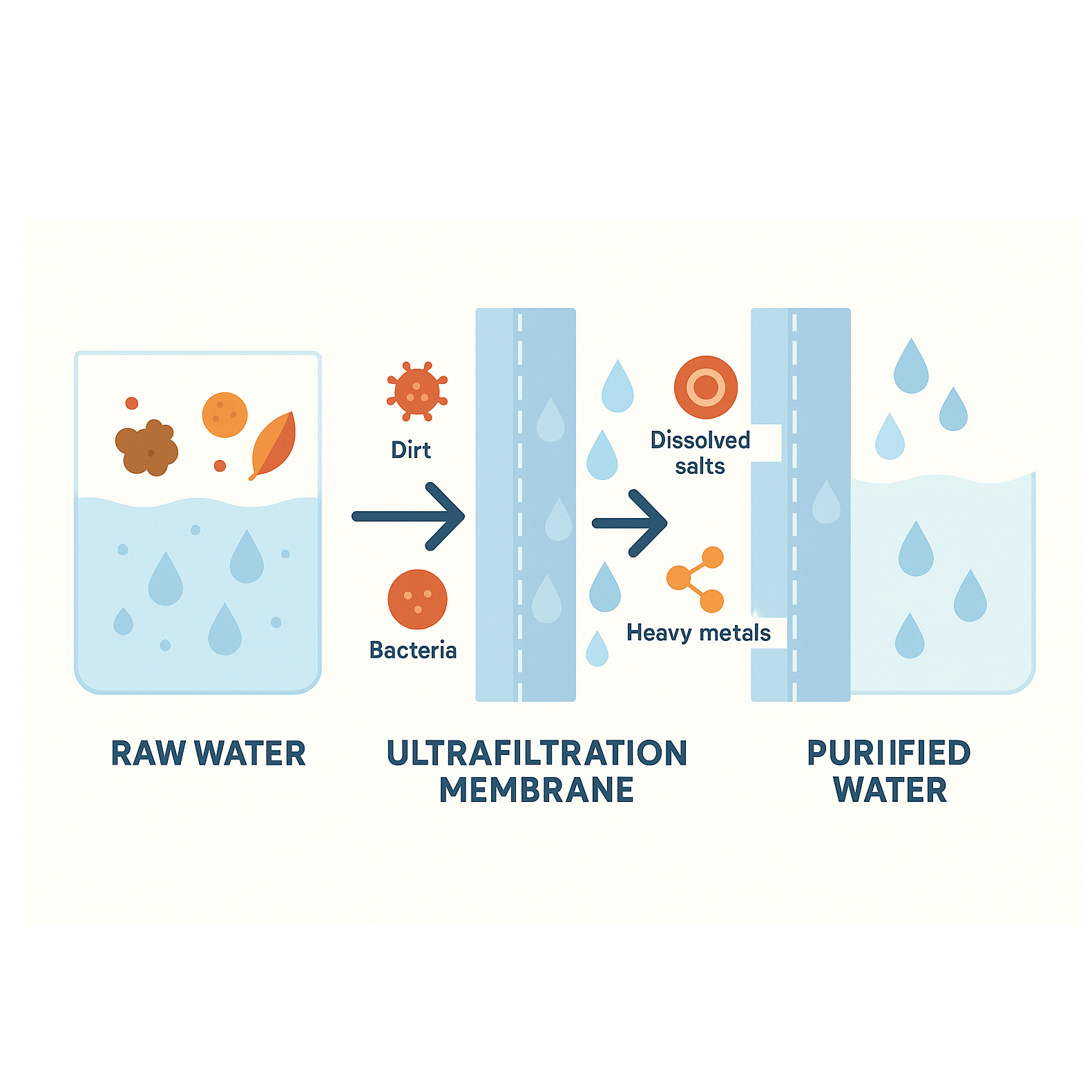

Ultrafiltration

Ultrafiltration (UF) is a water purification technology that uses a semi-permeable membrane to remove suspended solids, dirt, bacteria and other harmful microorganisms from water. UF membranes have pore sizes ranging from 1 to 100 nanometers. The MWCO is typically 1,000 to 500,000 Daltons, UF acts as a physical barrier, allowing clean water to pass through while blocking contaminants. It features larger pores compared to RO membranes, often used as a pre-treatment step for reverse osmosis systems, as it removes larger particles, organic matters which could otherwise damage or foul the RO membranes.

Key Features:

- Effective Microbial Removal: Eliminates bacteria, some viruses, and pathogens without the use of chemicals.

- Consistent Water Quality: Delivers clear, high-quality water even when raw water conditions vary.

- Energy-Efficient: Operates at low pressure, reducing energy costs compared to other filtration methods.

- Environmentally Friendly: Requires minimal or no chemical additives.

- Compact & Scalable: Ideal for everything from small homes to large industrial systems.

Applications of Ultrafiltration:

- Drinking Water Production: Removes suspended solids, bacteria, viruses, and turbidity from raw water.

- Pre-Treatment for RO/NF: UF is often used as a pre-treatment step to protect downstream RO or NF membranes from fouling.

- Wastewater Treatment: it is used to filter surface water, groundwater, and municipal water supply.

- Dairy Processing: Separates proteins (e.g., whey) or clarifies milk and juices.

- Beverage Clarification: Removes sediments from wine, beer, or fruit juices.

Nanofiltration

Nanofiltration (NF) is a membrane filtration process that operates at moderate pressure and uses membranes with a molecular weight cut-off (MWCO) of approximately 150–1000 Daltons. Nanofiltration uses semi-permeable membranes made of materials like polyamide, cellulose acetate, or ceramic composites. It has slightly larger pores and offers selective permeability—removing divalent and multivalent ions (e.g., calcium, magnesium, sulfate) while allowing smaller monovalent ions. This makes NF ideal for water softening and targeted removal of contaminants such as organic compounds, virus, bacteria and certain pesticides, all while retaining essential minerals in the water.

Key Benefits:

- Balanced mineral content: Delivers water that is clean, safe, and mineral-rich—ideal for drinking purposes.

- Enhanced taste and Odor: Removes organic compounds and other impurities that can affect the flavour and smell of drinking water.

- Selective ion removal: Effectively reduces water hardness by removing calcium and magnesium, while allowing health-beneficial minerals to remain.

- Lower operational costs: Operates at lower pressure than RO systems, resulting in reduced energy consumption.

Applications:

- Softening hard water for residential and commercial use

- Producing great-tasting, high-quality drinking water

- Removing heavy metals, organic pollutants, and specific pesticides

- Pre-treatment for reverse osmosis systems in industrial water treatment

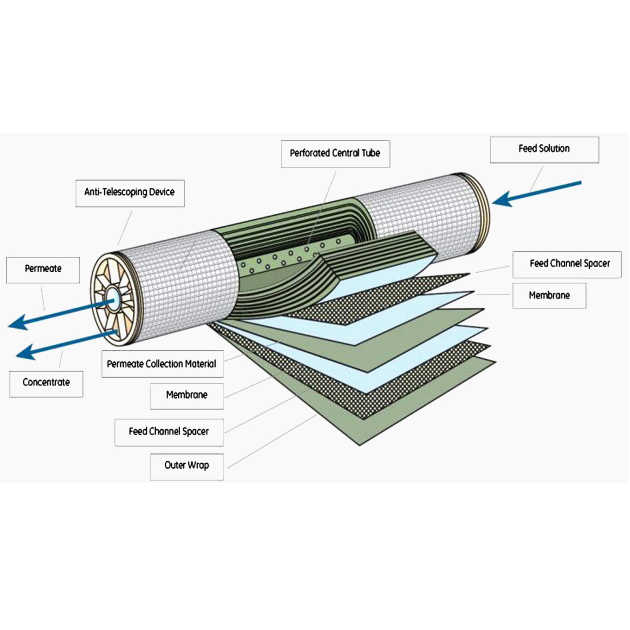

UF Modules in Water Treatment

Ultrafiltration (UF) modules are membrane-based filtration systems that remove suspended solids, bacteria, viruses and high-molecular-weight substances from water using fine pores, providing high-quality filtration with low energy consumption.

Principle of Operation:

UF membranes work based on size exclusion. Water is forced through semi-permeable membranes with pore sizes typically ranging from 0.01 to 0.1 microns. Particles larger than the membrane pores are retained, while water and smaller solutes pass through.

Key Features of UF Modules:

- Membrane Materials: Commonly made of PVDF (polyvinylidene fluoride), PES (polyether sulfone), or PAN (polyacrylonitrile), offering durability and chemical resistance.

- Configuration: Available as hollow fibre, spiral wound, or tubular modules.

- Operating Pressure: 1–5 bar (low pressure requirement).

- High Filtration Efficiency: Effectively removes bacteria, colloids, and turbidity.

- Back washable: Can be cleaned through automated backflushing and chemical cleaning cycles.

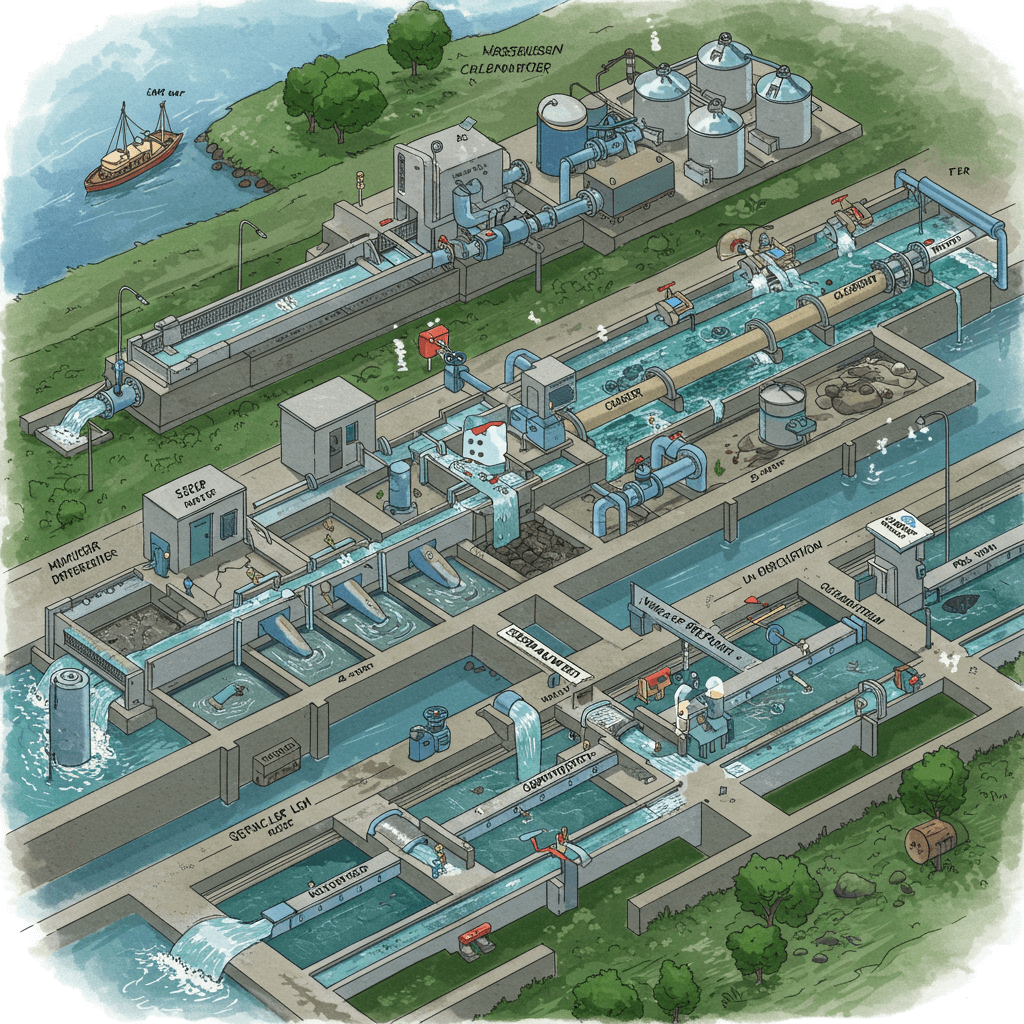

Environmental and Sustainability Impact

Membrane filtration technologies provide significant benefits for water conservation, energy efficiency, and waste reduction. Unlike traditional water treatment processes that rely heavily on chemicals or complex multi-step systems, membrane-based solutions offer:

- Reduced chemical use: Membranes work through physical separation, reducing the need for chemicals in the water treatment process.

- Water reuse: Membranes can treat wastewater to a high standard, allowing for water reclamation and reuse in industrial processes, agricultural irrigation, and more.

- Energy eƯiciency: With continuous advancements in membrane technology, systems are becoming increasingly energy-eƯicient, lowering operational costs while reducing the carbon footprint of water treatment plants.

At Pacific Aquatech, we are committed to developing filtration solutions that not only provide clean water but also contribute to environmental sustainability.